|

Mathematical Model of Thin Strip Casting

Hong Zhu, Guowei Liand Brian Thomas

Department of Energy, Armco

The thin strip casting process continuously solidifies 1-4 mm thick steel strip.

Once perfected, this process will offer huge energy and capital cost savings

over conventional casting and rolling processes for producing steel sheet

products. Mathematical models have been developed to predict and understand

fluid flow, heat transfer, and stress generation in this new process.

The results were evaluated in conjunction with measurements on a single-roll

pilot strip caster at Armco. They were used to understand and predict

freeze-up in the nozzle and strip thickness, distortion, and cracks.

A transient heat transfer model (STRIP1D) has been developed to simulate the

single-roll continuous strip-casting process. The model predicts temperature

in the solidifying strip coupled with heat transfer in the rotating wheel,

using an explicit finite difference procedure. The model has been calibrated

using strip thickness data from a test caster at ARMCO Inc. and verified with

a range of other available measurements. The strip/wheel interface contact

resistance and heat transfer was investigated in particular, and an empirical

formula to calculate this heat transfer coefficient as a function of contact

time was obtained. Wheel temperature and final strip thickness are

investigated as a function of casting speed, liquid steel pool depth,

superheat, coatings on the wheel hot surface, strip detachment point,

wheel wall thickness and wheel material.

Schematic of Single-Wheel Thin Strip Casting Process.

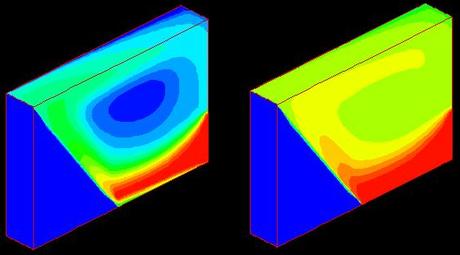

To obtain the superheat flux of the fluid flow in the nozzle, the velocity and

temperature distributions in the liquid poll were calculated by solving the

Navier-Stokes equations, k-e turbulence model, and energy balance equation

using the well-known SIMPLE algorithm with up-winding on a 60x40x20 staggered

mesh.

Superheat tmeperature field: (a) 10 seconds, (b) steady state.

More information can be found in the paper:

Li, G. and B.G. Thomas, "Transient Thermal Model of the Continuous

Single-WheelThin-Strip Casting Process", Metallurgical Transactions B, Vol. 27B(June), 1996, pp.509-525. Click here for a PDF version. (759 KB)

|