|

MIX1D: Intermixing during Grade Changes

Xiaoqing Huang and Brian Thomas

Continuous Casting Consortium

Intermixing in the liquid pool has been found to be significant and produces rejected steel during a grade change. A fast and accurate mathematical model (MIX1D) has been developed to simulate mixing in the tundish and the mold and accurately predict the composition profiles that develop in the solidified slabs and blooms. The model has been calibrated with three-dimensional model calculations and water model measurements, and verified with measurements at several plants. It is being further refined to run on personal computers at the steel plants to allow efficient grade classification, minimizing both customer complaints and yield losses. The effect of casting variables are now being investigated with the model to optimize grade changes for any casting operation.

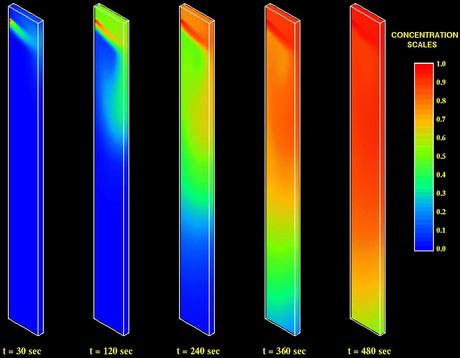

This figure shows the typical intermixing pattern obtained when the steel grade is suddenly changed from casting "blue steel" to "red steel" after opening a new ladle with a flying tundish change. The concentration contours were calculated with the 3-D finite difference fluid flow model.

For further information, see:

- Huang, X., and B.G. Thomas, "Modelling of Steel Grade Transition in Continuous Slab Casting Processes", Metallurgical Transactions B, Vol. 24B (April), 1993, pp. 379-393. Click here for 12.9 MB .pdf

- Huang, X., and B.G. Thomas, "Intermixing Model of Continuous Casting During a Grade Transition", Metallurgical Transactions B, Vol. 27B, No. 4 (August), 1996, pp. 617-632. Click here for 2.91 MB .pdf

- Thomas, B.G., "Modeling Study of Intermixing in Tundish and Strand during a Continuous Casting Grade Transition", ISS Transactions, in Iron and Steelmaker, Vol. 24, No. 12, Iron and Steel Society, Warrendale, PA, 1997, pp.83-96

Click here for 1.95 MB .pdf

|