|

3D Thermal Distortion and Stress in the Mold

Guowei Li and Brian Thomas

Continuous Casting Consortium

Thermal distortion of the mold during casting is important to mold life, since it induces permanent distortion and possible fatigue cracks. By affecting the internal geometry of the mold cavity, it is also important to heat transfer to the solidifying shell. To study thermal distortion of the mold, a three-dimensional, finite-element model has been developed using ABAQUS. It is being applied to provide boundary conditions for other models and is also being used to design molds with potentially longer life.

|

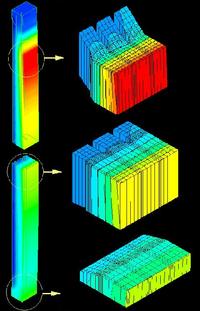

Heat Transfer Results

This figure shows the temperature distribution in a vertical section through the inside radius of a continuous casting slab casting mold wide face. The simulation domain of this vertical section of mold contains two and half cooling water channels with different depths and one bolt for restricting the thermal expansion toward mold hot face. The peak temperature occurs at meniscus, slightly below the peak of the imposed heat flux due to 3D effect. At mold bottom, a slight increase of the temperature was found, because of the end of cooling water channels.

|

Stress Analysis

Elastic-plastic-creep model was developed to conduct the stress analysis of the continuous casting mold. The x-stress distribution at maximum therml loading conditions on the deformed frame of mold is shown in this figure. The mold expand toward the mold hot face because the bolt forces are not sufficient. High x-direction compression occurs at the hot face at meniscus region, and small tension appears at the roots of the cooling water channels. The generalized plane strain assumption is applied in this simulation, which allows the mold to expand in all the directions. |

|

More information can be found in Guowei Li's Ph. D. Thesis:

Guowei Li, "Analysis of Thermal and Mechanical Behavior of High Heat Flux Facing Copper Walls," University of Illinois at Urbana-Champaign, Ph.D. Thesis, 1996.

Thomas, B.G., G. Li, A. Moitra and D. Habing, "Analysis of Thermal and Mechanical Behavior of Copper Molds during Continuous Casting of Steel Slabs", Iron and Steelmaker (ISS Transactions), Iron and Steel Society, Warrendale, PA, Vol. 25, No. 10, 1998, pp. 125-143. Click here for a PDF version. (1.00 MB)

|