Tundishes are holding vessels to supply a continuous flow of steel to the continuous casting mold and are fed from individual ladles. They are shaped like giant bath tubs.

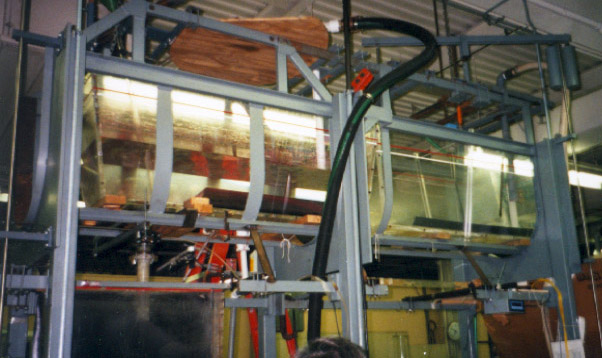

Water flows like molten steel (because it has nearly the same kinematic viscosity). Thus, water models are popular industry tools to study the flow pattern in the tundish.

The tundish flow pattern is designed to allow foreign particles in the steel to be removed, while avoiding "short circuiting" (where steel entering the tunidish quickly leaves into the mold) and avoiding excessive surface turbulence.